Another is fabricating molds or scaffolds, which can be cultured with cells in-vitro after fabrication. One is creating 3D cell-laden scaffolds that the cells are contained within the bioink. There are two main modes of 3D printing using for tissue engineering currently. The ideal role of 3D printing in tissue engineering is to provide the suitable microenvironment for cells to induce cell proliferation and differentiation toward the functional tissue. In addition, broadening choices in materials that can be processed by 3D printing offers researchers “recipe” to tune the biology performance of scaffolds. The advancement of 3D printing technologies has provided researchers and doctor’s abundant tools to promote the functional scaffolds, which meet the strict criterion of tissue engineering. Now, 3D printing is one of the most flexible technique enables direct manufacturing complex shape with high resolution, as well as processing highly customized medical products combined with image reconstitution technique. Then a ST-format file contained all the model information is exported to the 3D printing system to control the moving track of printing device and constructing the structure layer by layer.Įarly use of 3D printing focused on its raid manufacture process, which is suitable for pilot production in lab or factory.

3D PRINTING TISSUE ENGINEERING SCAFFOLD ADVANTAGE SOFTWARE

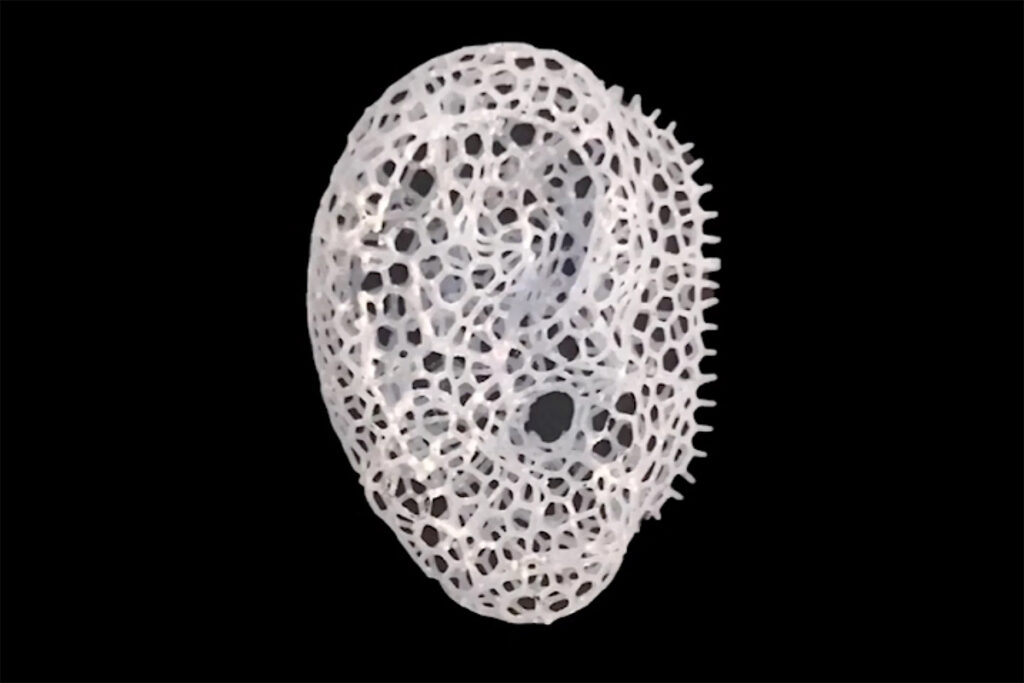

In all these cases, the printed structure is firstly modeled using a computer-aided design software packages, such as UG, CATIA, ProE, or other customized software. Over last thirty years, a variety of innovative 3D printing technologies have been developed, which can be categorized into three groups including powder-based 3D printing, ink-based 3D printing, and polymerization-based printing. The terminology “3D printing” firstly emerged was used to refer the work done at MIT in 1993, modifying a standard inkjet printer to a custom processing equipment. On the contrary, 3D printing is known as an additive manufacturing method, building the required structure layer by layer, or even pixel by pixel. In conventional processing methods, waste is cutting off from the raw material by milling, planning or grinding, and thus desired structure is obtained by these subtractive methods. Reform in materials processing methods arose from the pressing needs for high-performance and multi-functional materials for broad applications in energy storage, transportation, lightweight structures, and biomedical engineering, among which 3D printing are in the highest interest by the community of material science research. In efforts to address these issues, it is important to employ an advanced manufacturing technology, which is flexible enough to build the three-dimensional (3D) structure with complex inside feature. Now challenges for tissue engineering are the requirements for certain special structures, mechanical property, biocompatibility, and vascularization of tissues for implantation. This case confirmed that artificial organs stand a chance to substitute the insufficient supply of standard organ in transplantation, which can drastically decrease the demand for living tissue. In 2009, first artificial tissue was implanted successfully into a patient who suffered from the tracheoesophageal defect. Scaffolds are bulk bioactive materials with specific porosity and structure to contribute to the formation new tissues for completing the medical task. After years of powerful progress, a set of novel tissue culture, replacement and implantation technologies have been developed, allowing fabricating artificial extracellular matrices, namely scaffolds, to bear stem cells, growth factors, or other biological nutrients aiming at repair of tissue function. According to the broad range of application on cell types, it can be divided into skin, bone, vascular, kidney, and liver tissue engineering. Tissue engineering is a newly developing field of a combination of biology, materials method and engineering to develop functional substitutes for damaged tissues.

0 kommentar(er)

0 kommentar(er)